#3D Printing Ceramics Market

Explore tagged Tumblr posts

Text

Ceramic Substrates Market Will Reach USD 11,740.8 Million By 2030

In 2023, the ceramic substrates market was valued at USD 7,721.3 million. Forecasts indicate it will grow significantly, reaching USD 11,740.8 million by 2030, with a projected compound annual growth rate (CAGR) of 6.3% between 2024 and 2030. This growth of the industry can be credited to the increasing need for such materials in many sectors and the trend of the reduction of electronic…

View On WordPress

#3D Printing Materials Market#ceramics#Competitive Landscape#composites#growth prospects#innovations#Investors#Key players#Manufacturers#market drivers#metals#polymers#regulatory landscapes#researchers#Technological advancements#Trends

0 notes

Link

North America is projected to lead the global 3D Printing Ceramics market owing to advancement in the technology and presence of key industrial players...

0 notes

Text

The global 3D Printing ceramic market size was USD 1.24 billion in 2022 and is expected to reach a value of USD 3.74 billion in 2032 and register a revenue CAGR of 34.6% during the forecast period.

0 notes

Link

0 notes

Link

0 notes

Text

Hobby Ideas 🎨💻🎵🧁🪴

💰 Hobbies to Make Money:

Freelance Writing

Photography

Graphic Design

Web Development

Online Selling (e.g., Etsy, Amazon, eBay, Shopify)

Blogging

Stock Trading

Real Estate Investing

Affiliate Marketing

Freelance Consulting

💪 Fitness Hobbies:

Running

Yoga

Weightlifting

Cycling

Swimming

Martial Arts

CrossFit

Hiking

Rock Climbing

Dance (e.g., Zumba, Hip-hop)

☀️ Outdoor Hobbies:

Camping

Fishing

Birdwatching

Gardening

Geocaching

Kayaking

Mountain Biking

Backpacking

Stargazing

Horseback Riding

💻 Technology Hobbies:

Programming

Robotics

3D Printing

Virtual Reality (VR) Gaming

Home Automation

Drone Flying

Cybersecurity

App Development

Electronics DIY

PC Building

🎵 Music Hobbies:

Playing an Instrument (e.g., Guitar, Piano)

Singing

DJing

Music Production

Songwriting

Music Recording

Karaoke

Music Theory

Joining a Band or Choir

Vinyl Collecting

📚 Brainy Hobbies:

Chess

Sudoku

Crossword Puzzles

Board Games

Reading

Learning a New Language

Brain Teasers

Logic Puzzles

Math and Mathematical Puzzles

Astronomy

✨ Other Hobbies:

Cooking and Baking

Painting and Drawing

Pottery and Ceramics

Woodworking

Knitting or Crocheting

DIY Home Improvement

Model Building (e.g., model trains, airplanes)

Collecting (e.g., stamps, coins, vintage items)

Volunteer Work

Meditation and Mindfulness

#hobbies#creative#creative inspiration#inspiration#creativity#creating#learning#skills#life skills#advice#life advice

723 notes

·

View notes

Text

EVENT 002: BROOKLYN ART FESTIVAL.

The Brooklyn Art Festival has finally arrived! This three-day festival is located in the heart of Brooklyn, and aims to bring the community together through a multi-day offering of live music, artistic demonstrations, creative cuisine, and, of course, a sheer love of art. Volunteer-run, guests of all ages are welcome to join in this celebration of culture, creativity, and community. Admission to the event is free, though amenities including food, drinks, and marketplace offerings will be available for purchase. Street closures will be in place for the event; there is no public parking, but there will be a designated address for rideshare pick-up and drop-off. Walking, biking, and public transportation is highly encouraged!

DAYTIME FESTIVITIES (11AM - 6PM)

CHALK WALK — Stand and watch as professional chalk artists create jaw-dropping displays only utilizing chalk, or join in on the fun and create your own chalk masterpieces! All ages welcome. COMMUNITY MURAL — Leave your mark on a massive paint-by-number interactive mural! Grab a small tin of paint, a paintbrush, and a number, and do your best to stay in the lines. The end result (a beautiful abstract design of the Brooklyn Bridge, as designed by a local Brooklyn-born artist) won’t become evident until the end of the festival, so be sure to stop by on the last night to see what you’ve helped create! KIDSFEST (11AM-3PM) — Engage in all things fun at the kid-friendly kidsfest! Dance parties, inflatables, face painting, fairy hairstyling, elaborate puppet shows, and creative activities such as slime, tie-dye, ceramic painting, and puppet-making stations will be available. Though kid-aimed, all ages are welcome to engage in the fun! SKETCH 101 — You don’t need to be an expert to create a work of art, and the Sketch 101 sessions are here to prove that to you! Novices and professionals alike are all invited to sit and sketch as professional artists walk the audience through step-by-step instructions on how to draw beloved animated characters! Time slots: 12pm (Snoopy); 2pm (Mickey Mouse); 4pm (Shrek). ARTIST MARKET — Give back to the community by visiting the artist market! Featuring over 130 art vendors, there’s sure to be something there for everyone! Paintings, jewelry, ceramics, metalwork, glasswork, photographs, sculptures, watercolor, 2D and 3D art, fiber, prints, and much more will be available for purchase! COLORFUL CUISINE — During the day, make sure to visit one of the many food trucks and vendors available throughout the festival! Along with their typical menus, each vendor features at least one specialty treat in honor of the festival. From art palette cookies to minimalist trifles to deconstructed sandwiches, the food is sure to be a treat for the eyes and mouth! LIVE ENTERTAINMENT — Small stages have been assembled for the express purpose of demonstrating the amazing collection of performance art styles enjoyed by the borough! Take a picture of the schedule, and make sure to stop by each stage to experience a collection of entertainment ranging from rock bands, theatrical groups, opera singers, and more!

COME ALIVE AT NIGHT (6PM-10PM)

GALLERY WALK — The vibrant Brooklyn art scene is shown in all its glory at the nightly gallery walk. Grab a map and take a stroll through the borough, visiting designated ArtSpots: art exhibits hosted at local galleries, retailers, and restaurants. Enjoy light refreshments, striking artwork, and good ambiance. LIVE ENTERTAINMENT — The tempo slows down and the music continues through the night! A small selection of MusicSpots are also available, conveniently along the streets as patrons make their way through the Gallery Walk. Providing the perfect ambiance to the artist experience, be sure to stop and enjoy the music as you stroll from gallery to gallery! STUDENT SCHOLARSHIP SHOWCASE — Art students across Brooklyn have submitted some of their best work to the Brooklyn Art Festival’s Student Showcase! On display at the Haze Gallery (a featured ArtSpot) guests are invited to observe the art and submit a vote on which one piece of art impacted them the most. The artist who created the piece with the most votes at the end of the festival will be granted a small $2K scholarship to help support their artistic endeavors. BUBBLY BOOZE — The festival becomes an open container entertainment zone at night, and guests 21 and older are invited to taste an array of bubbly specialty booze made special for the festival! Each ArtSpot will have a specialty cocktail available, while a small selection of the daytime’s food vendors will return for the night’s light installation (along with a newly available nighttime cocktail). LIGHTS UP PERFORMANCE (9:30PM) — End your night with a synchronized light and music performance at Prospect Park! Light installations have been created and installed in the park, programmed to a musical arrangement that professional dancers have choreographed a routine to. Grab some food and something to drink, sit back, and watch as light, music, and dance all combine in dazzling collaboration!

OOC DETAILS BELOW!

OOC DETAILS.

IC Timeline: Canonically, the art festival occurs over the weekend, from May 10th — May 12th. OOC Timeline: Members will have between May 10th through May 17th to post their initial starters for the festival. After 5/17, no new starters are permitted, but members are free to continue their ongoing event threads until their natural conclusion. An announcement will be made on both days when the event has started and ended. Involvement: The Brooklyn Art Festival is organized by a nonprofit and run almost entirely by volunteers. All artists involved — asked to lead a Sketch 101 class, performing on a stage, featured in an exhibit, etc. — do so either voluntarily, or only for a small sum of money despite their professional status. As such, characters are welcome to both be guests of the event, or volunteers manning a booth, performing on a stage, hosting or featured in a gallery, or anything in between! Threads: Members are highly encouraged to engage in any art festival related threads during this time, and are free to continue non-event threads as well! Just please be sure to tag all event threads as bhqevent002 for differentiation purposes.

If you have any other questions about the event, please do not hesitate to reach out to the main!

#boroughs.event#bhqevent002#boroughs.announcement#finally here after being push back a month!!! <333

8 notes

·

View notes

Text

DIY: Ghostbusters Belt Gizmo

If you are a Ghostbusters fan, you will know what this Belt Gizmo is. Being a Ghostbusters fan myself, I have always wanted one of this to complete my Ghostbusters costume. First, I tried to find the best photo available of the circuit board and I mirrored it to use as the image for the other side of the circuit board. Printed it out on transparent sticker and stuck it on to stiff cardboard to make it look like a real circuit board.

Next, I had to create the graphics to replicate the various chips and components. These were also printed on transparent sticker and stuck on to cardboard. I used transparent stickers because they give a glossy look that made it look like plastic. Metal wires were attached to the "circuit board" where the white chips are then glued on top, to make it look like the "legs" of the chip.

For the ceramic disc capacitors, I stuck the stickers on to round discs I cut from a thin orange foam sheet. These were hot glued to the circuit board. Transistors and resistors were also attached. Hot glue were used in place of real solder. You can then just use a silver market to color these hot glue to make it look like real solder.

The Nixie tubes are harder to replicate. I thought long and hard about this and came out with a simple method. I designed the Nixie tube wire mesh and number design graphic and printed it on transparent sticker. These were then stuck in to transparent plastic tubes I cut from the body of a ball point pen. Finally, some aluminium sticker are used to complete the look.

Next, we wire some LEDs and glue some fake wires together and stuff it into the Nixie tube.

Now we can mount the Nixie tubes. The "rack" that the Nixie tubes were mounted on was made out of stiff cardboard. It was just a quick hack. I should probably redo this with a 3D printed part eventually.

With that completed, we can wire in the switch and battery holder. The switch is hot glued under the Nixie tube rack and the batter holder just slots into the space under the Nixie tubes.

Another detail is the caps above the Nixie tubes. Again, another quick hack.

Lastly, I also attached an old telephone cord and some random circuit board that I mounted a belt clip behind it.

That's it, the belt gizmo is done! What do you think?

9 notes

·

View notes

Text

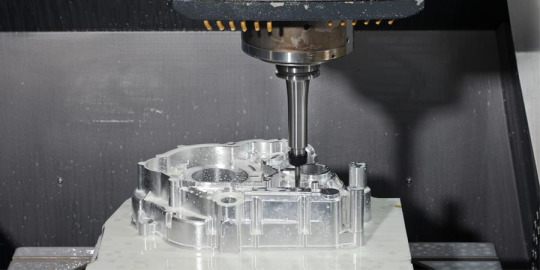

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

Additive Manufacturing Market, Industry Forecast, 2024–2030.

Additive Manufacturing Market Overview:

Sample Report :

Additionally, Increasing focus on metal additive manufacturing technologies. Researchers and companies have been actively working on expanding the range of metals and alloys available for AM. This includes not only traditional metals like titanium, aluminum, and stainless steel but also high-performance alloys for specialized applications. The development of new metal powders suitable for various AM processes has been a focus area. The integration of Additive Manufacturing with traditional manufacturing processes in companies were exploring hybrid manufacturing approaches that combine the strengths of additive and subtractive methods. This integration aimed to leverage the design flexibility of Additive Manufacturing and the efficiency of traditional methods to optimize production workflows. These factors impact the growth in Additive Manufacturing Market.

Market Snapshot:

Additive Manufacturing Market — Report Coverage:

The “Additive Manufacturing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Additive Manufacturing Market.

AttributeSegment

By Type

● Materials

● Systems

● Services & Parts

By Material

● Plastics

○ Acrylonitrile Butadiene Styrene (ABS)

○ Polylactic Acid (PLA)

○ Polyethylene (PE)

▪ High-Density Polyethylene (HDPE)

▪ Low-Density Polyethylene (LDPE)

▪ Linear Low-Density Polyethylene (LLDPE)

▪ Others

○ Polycarbonate (PC)

○ Polypropylene (PP)

○ Polyethylene Terephthalate (PETE)

○ Nylon

○ Others

● Metals

○ Iron

○ Steel

○ Silver

○ Aluminum

○ Copper

○ Titanium

○ Gold

○ Zinc

○ Others

● Ceramics

○ Glass

○ Silica

○ Quartz

○ Others

● Others

By Technology

● Powder Bed Fusion

○ Direct Metal Laser Sintering (DMLS)

○ Selective Laser Sintering (SLS)

○ Selective Laser Melting (SLM)

○ Electron Beam Melting (EBM)

○ Others

● Binder Jetting

● Directed Energy Deposition

○ Laser Deposition Technology (LDT) excluding LCT

○ Laser Additive Manufacturing (LAM)

○ Laser Metal Deposition (LMD)

○ Laser Engineering Net Shape (LENS)

○ Laser Cladding Technology (LCT)

○ Electron Beam Additive Manufacturing (EBAM)

○ Wire Arc Additive Manufacturing (WAAM)

○ Laser Deposition Welding (LDW)

○ Others

● Material Extrusion

● Material Jetting

○ Drop On Demand (DOD)

○ Polyjet by Object

○ Others

● Vat Polymerization

○ Stereolithography (SLA)

○ Digital Light Processing (DLP)

○ Continuous Liquid Interface Production (CLIP)

○ Others

● Others

By End-Use Industry

● Industrial

● Aerospace

○ Commercial

○ Military

○ Others

● Consumer Goods

○ Furniture

○ Watches and Jewelry

○ Shoes and Soles

○ Others

● Oil & Gas

● Automotive

○ Passenger Cars

○ Light Commercial Vehicles (LCV)

○ Heavy Commercial Vehicles (HCV)

○ Others

● Medical & Healthcare

● Electrical & Electronics

○ Conductors

○ Resistors

○ Sensors

○ Semiconductors

○ Others

● Building and Construction

○ Residential

○ Commercial

○ Industrial

○ Infrastructure

The COVID-19 pandemic had a mixed impact on the Additive Manufacturing (AM) market. While disruptions in global supply chains initially posed challenges for material sourcing, the flexibility of AM processes proved beneficial in addressing urgent needs for medical equipment and components. The demand for 3D printing surged during the pandemic, with AM technologies being utilized for the rapid production of ventilator parts, face shields, and other critical supplies. The crisis highlighted the agility of AM in responding to unforeseen challenges and increased awareness of its potential across various industries.

Inquiry Before Buying :

The situation in Ukraine had indirect effects on the Additive Manufacturing (AM) market, primarily through broader geopolitical and economic repercussions. Disruptions in supply chains, especially for metals and other raw materials used in AM processes, were potential concerns. Additionally, uncertainties in global markets may have influenced investment decisions and R&D activities in the AM sector. However, the impact varied depending on the resilience of individual companies and their exposure to the geopolitical developments.

Key Takeaways:

North America Dominated the Market

Geographically, in the Additive Manufacturing market share, the North America region has held a dominant market share of 41% in 2023, Rising government investments and projects in the United States for additive manufacturing have also raised the growth of the market. For instance, to address the challenges in single laser melting (SLM), America Makes awarded GE Global $2.6 million to build an open-source, multi-laser production machine and AM platform. Additionally, in Canada, the rising partnership between research universities in the field of additive manufacturing is also influencing the growth of the market. U.S. is anticipated to lead the global additive manufacturing market with the largest installed base for 3d printer in the world. With such a dominant presence of the 3d printers in the country U.S. is likely to contribute more than one third in the revenue generated by additive manufacturing worldwide.

Metal is the Fastest Growing Segment

In the Additive Manufacturing Market forecast, the Metal segment is estimated to grow with a CAGR of 23.5% during the forecast period. Metals are a better option for 3D printing compared to plastics, as they have more industrial usage. Often the 3D metal printing shows itself to be unique as the new technologies can readily surpass what was offered by traditional processes. In AM of metals a powder feedstock or more rarely a wire is fully melted by the energy input of a laser or electron beam and transformed layer by layer into a solid part of nearly any geometry. The most popular processes for AM of metals are Laser Beam Melting (LBM), Electron Beam Melting (EBM) and Laser Metal. In a survey conducted across the globe, about 23% of the 3D printing materials used are metals. The 3D printing metals segment is also poised to grow as it has a competitive edge over other plastic materials used in 3D Printing. Metal 3D printing is too expensive, furthermore other companies, like Desktop Metal and Markforged, are developing approaches to manufacture affordable metal 3D printers.

Schedule A Call :

Aerospace to Hold Largest Market Share

According to the Additive Manufacturing Market analysis, the Aerospace segment is estimated to hold the largest market share of 34% in 2023, the aerospace and defense industry is a perfect example of how to use additive manufacturing (AM) (commonly referred to as 3D Printing) to produce components that are heavier and lighter than parts manufactured using conventional manufacturing methods. Additive manufacturing or 3D printing has applications in the aerospace industry such as engine compartments, cabin accessories, air ducts among others. NASA researchers are looking into how electroplated SLA parts perform in space. Engineers at NASA’s Goddard Space Flight Center designed brackets that were 3D printed on printers, electroplated, and sent to space aboard a summer 2022 SpaceX commercial resupply services (CRS-25) mission to the International Space Station (ISS). The results could inform how NASA and possibly other aerospace manufacturers may incorporate electroplating and additive manufacturing into potential future product plans.

Ease of Manufacturing Complex Design

he basic physical difference in how objects are made with the additive manufacturing process produces some major functional differences when compared with other traditional manufacturing processes. The most significant of these functional differences is the ability of additive manufacturing to produce complex geometries that would be difficult or impossible to achieve using conventional manufacturing methods. These intricate geometries are also stronger and lighter than their conventional counterparts. Additive manufacturing eliminates the additional costs normally associated with creating more complex objects. A highly complex component usually costs much more using conventional methods. This is primarily because conventional fabrication methods rely on the conversion of three-dimensional illustrations into two-dimensional drawings for fabrication, as well as the labor cost of assembling such components. However, regardless of the complexity of a component, the method in additive manufacturing is the same. Thus, no additional cost is incurred for manufacturing complex designs using additive manufacturing.

Buy Now :

Relatively Lower Production Cost for Rapid Manufacturing

The manufacturing companies experience various benefits while using additive manufacturing methods to produce objects. Since the complexity of the component has little or no impact on the manufacturing time and costs, additive manufacturing is ideal for low-cost production as well as small and (very) large series. Design changes can be implemented quickly at a low cost. Metal structures are made up of atom by atoms in additive manufacturing, as opposed to subtractive approaches like chemical etching. As a consequence, almost every piece of metal is utilized during the production process, with almost no waste of material and reducing material wastage. When using additive manufacturing, all of the extra features that are needed for the assembly, such as fasteners, brazing, or welding, can be omitted. Thus, additive manufacturing also reduces assembly costs.

Difficulty in Producing Large Single Parts

Even if additive manufacturing were to dramatically increase production speed and volume performance, it would still be unable to manufacture large single parts. This is yet another major challenge confronting additive manufacturing researchers as they pursue new applications for 3D printing technology. Arc-based wire feed metal AM was chosen as the best process to produce large metal parts. While metal powder bed printers are available commercially, they are not currently capable of producing large-scale metal parts. Therefore, arc-based wire feed technology provided the most cost-effective solution. The building envelope for current additive manufacturing technologies is limited, meaning even larger components that can be printed must still be assembled by mechanical joining or welding.

For More Details on This Report — Request for SampleKey Market Players:

duct/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Additive Manufacturing Market. The top 10 companies in this industry are listed below:

Proto Labs, Ltd.

3D Systems, Inc

Stratasys Ltd.

Desktop Metal

Autodesk, Inc.

Materialise NV

Markforged

Optomec, Inc.

Dassault Systemes

Titomic Limited

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Netherlands and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

For more Automation and Instrumentation Market reports, please click here

0 notes

Link

#adroit market research#image editing software 2022#image editing software trends#3d printing ceramics

0 notes

Text

Future Stiles: Leading the Way in Innovative Tile Manufacturing

Introduction

Future Stiles is a brand that leads the industry in tile manufacturing. The company confidently focuses on new quality and design solutions. With a wide portfolio of products consisting of ceramic, porcelain, policy, and specialty products such as handmade and textured tiles, Future Stiles has made their name as a preferred company among homeowners, architects, and designers. It is well acknowledged that Future Stiles is at the forefront of the tile industry in terms of great design and at the cutting edge of tile technology. This paper looks at the growth of the firm, the products available to the customers, and the ideals that make the company better than the competitors.

The Future Stiles Vision

Central to Future Stiles’ scalar growth is a revolutionary vision to change the spaces as well as the way of life of their target clients. The objective of this company is to combine design and art creating a product that is both strong and practical. Future Stiles is always focused on the product and how it can improve the market, this has allowed the company to continue introducing new ideas and ways of thinking that are both innovative and beautiful. Designing people’s homes has never been as simple as it is today in the Future Stiles world – each product category is designed by the latest trends and suggests attention to detail and the requirements of the consumers.

Commitment to Quality

Quality is a core principle of Future Stiles. The company puts each tile through a rigorous process to ensure that it’s capable of enduring high levels of stress and that the finish and performance are up to standard. At every stage of the production process, from materials to final tiles, Future Stiles assumes the responsibility so that every tile is well made and stays that way for years. Because of this, the general public knows them, and it has become a highly reputable organization in the eyes of customers other professionals, and competitors.

Innovative Design and Technology

Turning their ideas into reality is probably the best measure of the founders’ business creativity. The brand actively promotes investing in r&d in the search for new textures, patterns, and materials. Technology has greatly assisted in the production of aesthetic tiles that are designed for durability, and requirements such as easy cleaning and maintenance. For example, for many homes, life-like animated images become helpful in creating high-definition printing, while specialized glazing techniques achieve texture-embedded manufacturing.

Product Range

The extensive product offerings of Future Stiles in combination with its different looks makes them suitable for accomplishing a wide range of tasks. Here are some of the main product groups:

Ceramic and Porcelain Tiles

Ceramic and porcelain tiles are known to be some of the most popular products sold at Future Stiles. Considering their versatility and strength, these tiles can be used for floors, walls, and even outdoors. Porcelain and ceramic tiles from Future Stiles come in a variety of colors, textures, and sizes leaving them appropriate for almost any style from contemporary to classic.

Handmade Tiles

Handmade tiles offer a personal touch to any space. No two tiles are the same because they are all handmade which means that they all have a different finish and texture. If you are in search for that realistic handmade effect, Future Stiles has a collection of those tiles to suit a warm, rustic, or eclectic theme. Such tiles can be used for vertically painted walls, ceramic tile planes, and other accent features in which attention is required.

3D Textured Tiles

3D tiles are quite in demand as they add depth and dimensionality to various spaces when used by interior designers and homeowners alike. Future Stiles has dozens of textured tiles starting from subdued wavy lines to striking geometry. Such tiles are appropriate for accent walls making the walls more exciting in their place and suitable for living rooms, bedrooms, or commercial interiors.

Mosaic Tiles

Mosaic tiles are a fascinating method for applying color and texture to the surface. Future Stiles’ mosaic tiles are suitable for pools, bathrooms, and kitchen backsplashes. They can be made from glass, ceramic, and stone among other materials.

Eco-Friendly and Sustainable Options

Recognizing the significance attached to environmental issues, Future Stiles has diversified its product line to cover eco-friendly tiles. Tiles of this kind are produced in an eco-friendly manner and from recyclable materials as part of the company's policy of limiting environmental degradation.

Customer-Centric Approach

Future Stiles has a good understanding of its clients and always works to ensure that they are satisfied with their products or services. Along with design consultations and product selection, the company’s installation options are designed in a way that enables the clients to choose the most appropriate tiles for their projects. This customer-first approach has enabled Future Stiles to acquire a loyal clientele with established networks in the industry.

Applications Across Spaces

Future Stiles’ tiles are suitable for a wide range of applications:

Residential: Future Stiles has a tile to suit the needs of every part of the house, including the kitchen, bathroom, living room, and outdoors enhancing the beauty and functionality of the homes.

Commercial: Future Stiles products are also used in restaurants, hotels and offices bringing durability and beauty to the spaces.

Outdoor: Future Stiles has also designed tiles that are resistant to all outdoor conditions for patios, walkways and pool areas as these areas have to be beautiful while still being practical.

Future Goals and Vision

Future Stiles will develop as a company, but their goals to create innovations and maintain high quality will stay. The company also plans to broaden its range of products, use eco-friendly materials, and adopt the current fashions in the industry. Future Stiles products will continue to be available for a wider range of consumers without compromising their standards of quality.

Conclusion

Future Stiles is not only a manufacturer of tiles it is a brand that aims to improve space through unique and superior tile products. Future Stiles has developed into a tile industry leader by upholding design, quality, and customer service. For homemakers, designers, and architects who look for stylish yet tough tiles, Future Stiles offers a world of possibilities. As the company continues to evolve, its commitment to transforming spaces with quality and creativity remains unwavering.

0 notes

Link

#adroit market research#consent management trends#consent management services#consent management size#3d printing ceramics

0 notes